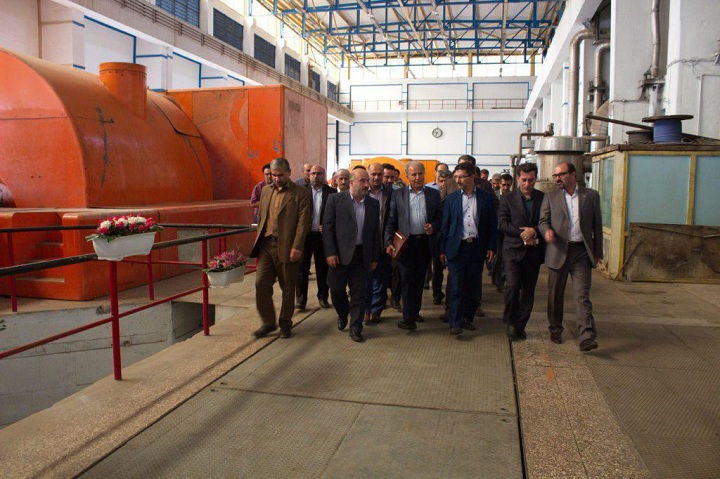

Inauguration of the Renovation and Rehabilitation of the Steam Turbine of Shahid Beheshti Power Plant, Lowshan

Lowshan Shahid Beheshti Power Plant was launched in 1972. This complex is one of the thermal power plants with a production capacity of 360 MW, which includes two 60 MW gas units and two 120 MW steam units. Over the course of nearly 5 decades, the steam turbines have not been in good working condition since the continuous operation of this plant, turbine blades and shells have been corroded and fatigued over time, resulting in lower unit production capacity.

Mehrdad Ali Gholami, CEO of Lowshan Thermal Power Plant, on the sidelines of the opening ceremony of the localization project for the steam turbine of the plant, told reporters: "The power generation capacity of the Loshan Shahid Beheshti power plant units has been limited to 40 MW due to the burnout of devices in recent years, by using the localization capability to rehabilitate the steam turbine, we managed to return it to the amount of 120 megawatts. Gholamreza Mehrdad, General Director of the Technical Support Office of the mother company of the thermal electric power company, in this program, emphasized on the importance of implementing the project Rehabilitation and recovery of the existing production units, he also has pointed out that due to the investment restrictions and the lengthy time of implementation of the projects for the construction of new power plants, the way out of the shortage of electricity in peak periods consumes the most from the power and recovery of lost power in Power units are available.

In this regard, due to the lack of support of the foreign manufacturer of power plant equipment due to the large amount of equipment, a tender was held in 1395 by Loshan Power Company. Finally, in competitive conditions, with the presence of domestic and foreign competitors, TABA Engineering & Services Co. was selected as a rehabilitation contractor, using domestic specialists and utilizing renewed engineering and reverse engineering processes, with less than one-third the cost of similar foreign projects reached the stage of exploitation.

Ali Nikbakht, Managing Director of TABA Engineering & Services Co., said: "This project is based on the existing engineering, research, academic and manufacturing capacities in the country in three phases of engineering, assembling and installing parts on turbines for less than five months. And this is achieved only with the help of precise planning and management of the project as well as the pursuit of the supervisor of the employer. Therefore, it is ready to carry out similar projects with the aim of localizing the construction of components at other power plants of the country.

The engineering phase of this project involves various steps including measuring the dimensions of used parts and estimating their initial dimensions, analyzing and determining the metallurgical properties of blades and rims, drawing up three-dimensional models and building drawings, compiling a quality control and knowledge development casting, simulation, melting and vibration analysis. In this direction, the engineering and technical team of TABA Company, in cooperation with the new technologies Institute of Amir Kabir University of Technology, has been developing the necessary technical knowledge.

Majid Zarei, Member of TABA’s board of directors, said that the main challenge in this project was the lack of technical specifications and access to a sample of parts, which, in the course of time, was subject to major repairs and engineering documentation.

The construction phase of the project began with the development of shell fusions and turbine rings, as well as aluminum blades, and continued with casting operations at the domestic well-developed factories. The magnitude of shells, the volume of molten material, the control of mechanical properties , graining and the shape of the metallurgical structure have a special significance in obtaining favorable results. Managing director of the project, Manouchehr Shahmiri, said: "The machining of shells, despite the large dimensions, shards and blades, required high accuracy of adaptive telescope, which was carried out by all domestic experts." The assembly of new parts made at the turbine of the power plant was also carried out by the contractor in a very short time with the cooperation of the specialists of the Lowshan Power Management Company.

By implementing this knowledge-based project, the power of the steam generating unit of the Shahid Beheshti Power Plant, after the rehabilitation, has come to its forefront. The implementation of this project by TABA Engineering and Services Co., with the cooperation of more than 20 domestic industrial production units, related laboratories and universities, has been a reliable step towards achieving the objectives of resilient economy, production and employment. Dr. Hosseini, the head of the Faculty of Mechanics at Amir Kabir University, another speaker of the ceremony, referring to the memorandum of cooperation of the university with TABA, announced that the link between the university and the industry would enhance scientific and research capabilities and lasting measures. Asghar Agha Kusha, Director of the whole improvement of power plants and the environment and The parent company of Thermal Power Company stated at the end of the program that "It is hoped that the successful implementation of the rehabilitation project of the Lowshan power plant can serve as an efficient example of the rehabilitation culture in other power plants of the country thanks to the presence of capable contractors