operation and maintenance

Implementation, deployment, and promotion of modern integrated operation and maintenance systems for power stations, oil & gas refineries, and petrochemical plant

Standardizing and customizing the operation and maintenance activities in order to achieve the expected targets of O&M KPIs such as Reliability, Availability, Maintainability, Safety (RAMS) in the best efficient manner by:

- Applying the latest OEM recommendations

- Boosting HSE factors

- Removing production constraints

- Implementing suitable maintenance methods complying with customer interests

- Comprehensive energy auditing

- Providing solutions to increase plant productivity

Operation:

- O&M services and optimal management for power, oil, gas, and petrochemical plants in short and long-term contracts.

- Recognize the various factors constraining the power generation and providing strategies for dealing with them.

- Recognize the various factors causing efficiency degradation and providing solutions to enhance them.

- Modify operation and maintenance procedures of equipment and parts to reduce system losses and depreciation.

- Setup modern digitized maintenance systems.

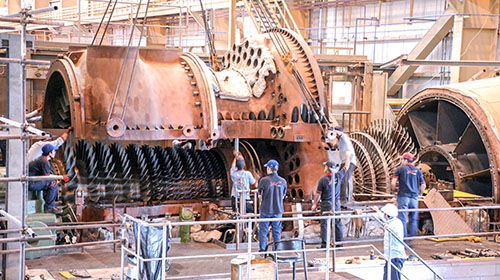

Maintenance and Repair:

- Performing and supervising periodic maintenance, hot gas path inspection, overhaul, LTE, and RI of various types of gas & steam Turbine/Generator.

- Maintenance and revamping of turbo-compressors in oil & gas refineries and petrochemical plants

- Life cycle assessment of capital parts

- Refurbishing, rehabilitation, and renovation of power plants and equipment