5 June, the World Environment Day; Subject: What environmental results follow the implementation of cooling plans?

On the eve of the World Environment Day (5 June), we have taken a look at the environmental results of the implementation of cooling projects:

Author: Dr. Mohammad Saeed Fakhimjoo, Engineering and Research and Development Specialist

-

Environmental results of implementing cooling plans

-

fuel consumption

-

The use of evaporative cooling system in gas turbines leads to a decrease in the inlet temperature to the compressor and the entry of cooler air that is denser leads to an increase in the air mass flow rate. With more air coming in, more fuel is needed in the combustion chamber. Therefore, at first glance, gas turbine fuel consumption increases when the evaporative cooler is in the circuit. However, this increase in consumption is accompanied by an increase in the production power of the turbine. Therefore, it is more accurate to evaluate the amount of fuel consumption per production power.

The data obtained from the operation of evaporative cooling in Kashan Power Plant show that during a one-month operation period, on average, about three percent in gas fuel and about four percent in diesel fuel for each megawatt of electricity produced, consumption reduction occurs. In different conditions, this amount is at least 1.7 percent and at most 5.7 and 6.7 percent for gas and diesel, respectively. This number is equivalent to less consumption of 7.5 kg of natural gas and 13 kg of diesel fuel for producing one MVh of electrical energy.

With the average operation of the cooling system for about 10 hours during the day and during the four-month peak period in Kashan power plant, an average equivalent of 2365 tons of natural gas or 4000 tons of diesel fuel was consumed, which will result in significant savings in the long term. For a better understanding of this matter, if it is assumed that this saved fuel is sold at the global market, it will earn the country an income equal to 850 thousand dollars for gas or 6.3 million dollars for diesel fuel. It should be noted that this amount was calculated only for one power plant with two gas units.

Efficiency

The drop in power generation efficiency is one of the effects of increasing ambient temperature on gas turbines. This decrease in efficiency will lead to the non-optimal use of valuable energy resources. The results obtained from the performance of the evaporative cooling system in Kashan power plant show that this system is able to increase the performance efficiency of the gas turbine in the hot season. In different temperature and humidity conditions and in the case of natural gas fuel, the efficiency of gas turbine production increases by 2.3% on average, and this number reaches 1.5% for diesel fuel.

-

Air pollutants

One of the problems of producing electric energy using fossil fuels is the production of air pollutants. Burning natural gas to produce energy compared to other fuels such as coal or gasoline results in the emission of lower amounts of air pollutants and carbon dioxide. The clean-burning properties of natural gas have increased the use of this fuel to produce electrical energy. Consider the following equation:

CH4 + 2O2 > CO2 + 2H2O

According to the above equation, if natural gas is completely burned, the result will be carbon dioxide gas and water vapor. However, due to various reasons, this gas is always not completely burned and leads to the side emission of other air pollutants such as nitrogen oxides and carbon monoxide.

In gas turbines, the burning process leads to the release of air pollutants and the reduction of air quality. As mentioned, by using the evaporative cooling system, the fuel consumption of the turbine is increased and subsequently the production power is increased. Similarly, with the increase in fuel consumption, the emission of air pollutants from the gas turbine exhaust also increases. But similar to what was said about fuel consumption, the amount of emitted pollutants decreases in proportion to the production power. On the other hand, reducing the intake air temperature will reduce incomplete combustion and produce less nitrogen oxides.Due to the lack of real-time monitoring of the pollutants emitted from the chimney outlet, there has not been enough data to investigate the effect of the cooling system on the amount of pollutants emitted. Therefore, in order to investigate this factor, software simulation of gas turbine with gas fuel was performed in two cases of no cooling system and also the presence of cooling on the air inlet of the turbine compressor. The results of this modeling are shown in the following diagram:

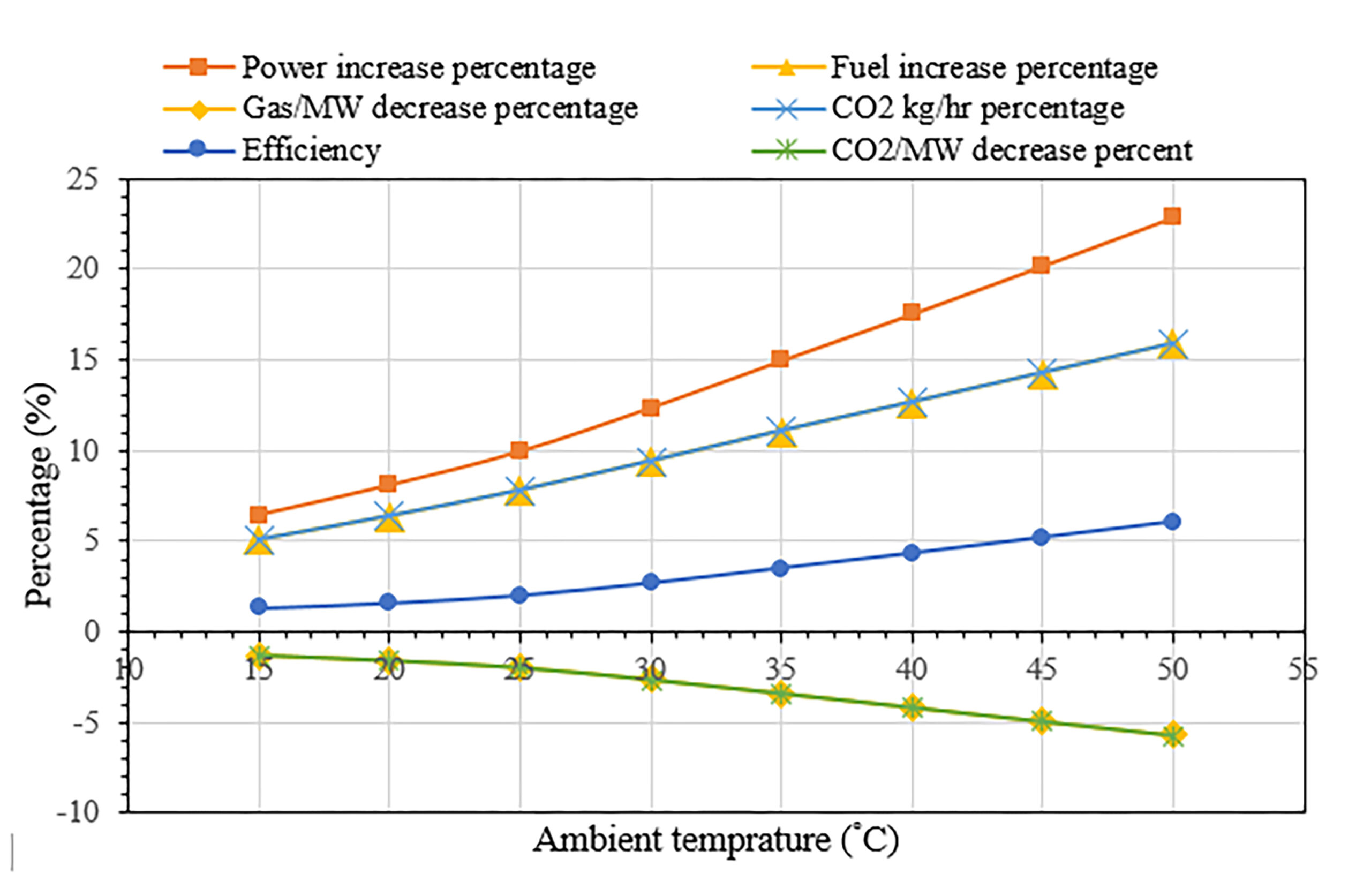

Percentage changes of different variables of gas turbine of Kashan Power Plant with wetted-media cooling systems

Percentage changes of different variables of gas turbine of Kashan Power Plant with wetted-media cooling systems

What are presented in the above graph, are the results of the simulation of Mapna V.94.2.5 turbine, for the weather conditions of Kashan city in a relative humidity of five percent. As can be seen, by using the wetted-media evaporative cooling systems, the production power of the turbine has increased up to 22.88% at a temperature of 50 degrees Celsius. The effectiveness of this sistem grows up with increasing temperature and decreasing humidity. Corresponding to the increase in temperature, the amount of fuel consumed and subsequently the carbon dioxide produced has increased up to 15.88%. However, if the amount of fuel consumption and released carbon dioxide is taken into consideration according to the turbine power, at a temperature of 50 degrees Celsius and a humidity of five percent, per megawatt of turbine electricity production, the amount of fuel consumption and carbon dioxide pollutant production is up to 5.7% is reduced.

According to the results presented in this subsection, it is clear that the use of wetted-media evaporative cooling systems in the air inlet of the compressor of gas turbines is a plan in line with the environmental goals and a measure to improve the environment of the region and the country. Reduction of fossil fuel consumption as one of the country's main energy sources is one of the advantages of using this plan. On the other hand, by reducing the emission of pollutants caused by burning fossil resources, a step is taken to improve air quality.

The downside of using this system is its water consumption. The investigation and calculations show that this consumption is not a significant number compared to other urban consumption in the country and this consumption can be compensated with corrective measures.

In addition to all the mentioned advantages, one of the most important results of using this plan is to increase the production capacity of the country's power plants during the peak consumption of the grid, without spending a lot of money to build a new power plant or to create an excess capacity over the country's power generation capacity. Preventing grid outages during peak electricity consumption in the hot season of the year will have major socio-economic benefits for the country. Preventing power cuts in industries and reducing production in the country and preventing blackouts in urban areas are among the things that the use of these systems will bring to the country without spending a lot of money.