Engineering and manufacturing of shell, ring and blades stage 1-6 LP and 16-32 IP of Siemens steam turbine of Lowshan power plant

| Project name | Turbine type | Project site | Client |

| Engineering and manufacturing of shell, ring and blades stage 1-6 LP and 16-32 IP of Siemens steam turbine of Lowshan power plant | Siemens | Lowshan Shahid Beheshti Power Plant | Lowshan Power Generation Co. |

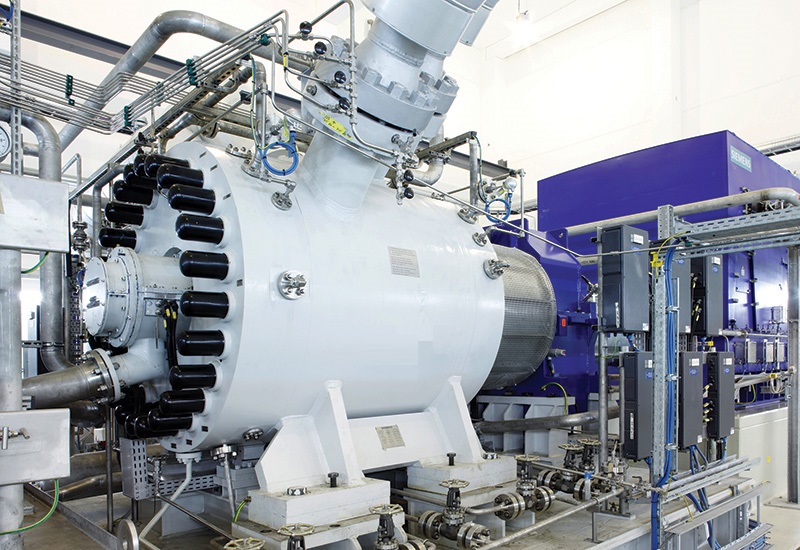

The shell or casing or bladering of all types of turbines are strategic equipment in the field of power plants to produce electricity. The shell and stationary and rotary blades of the 120 MW Shahid Beheshti Lowshan power plant steam turbine with a nominal speed of 3000 rpm, inlet temperature of 530 degrees Celsius and inlet pressure of 120 bar are completely engineered and produced by TABA Engineering and Service Company.

In the complex and difficult process of construction and finalization of this super project, various steps were taken. First, after various consultations, the used parts and assembly conditions were examined. After that, the available evidence was carefully discussed. As the main activities of the company began, accurate measurements and 3D scans were an inevitable requirement of this stage. Taba Engineering and Service Company, by having an expert engineering team and using the necessary software and technical know-how, took into account the depreciation of the parts and the lack of access to some assembly areas, re-designed the roof and produced the new documents needed for construction. Material analysis for different parts as well as for testing raw materials is one of the other necessary things that the company does. Also pecialized standards belonging to the main turbine manufacturers are used in all stages.

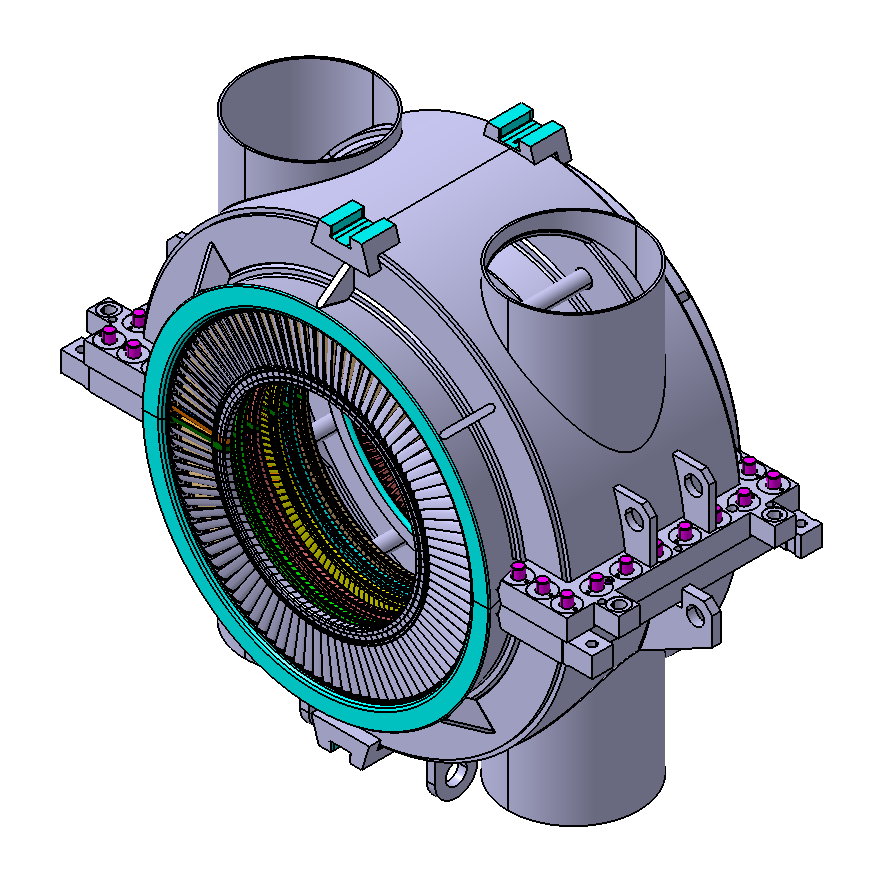

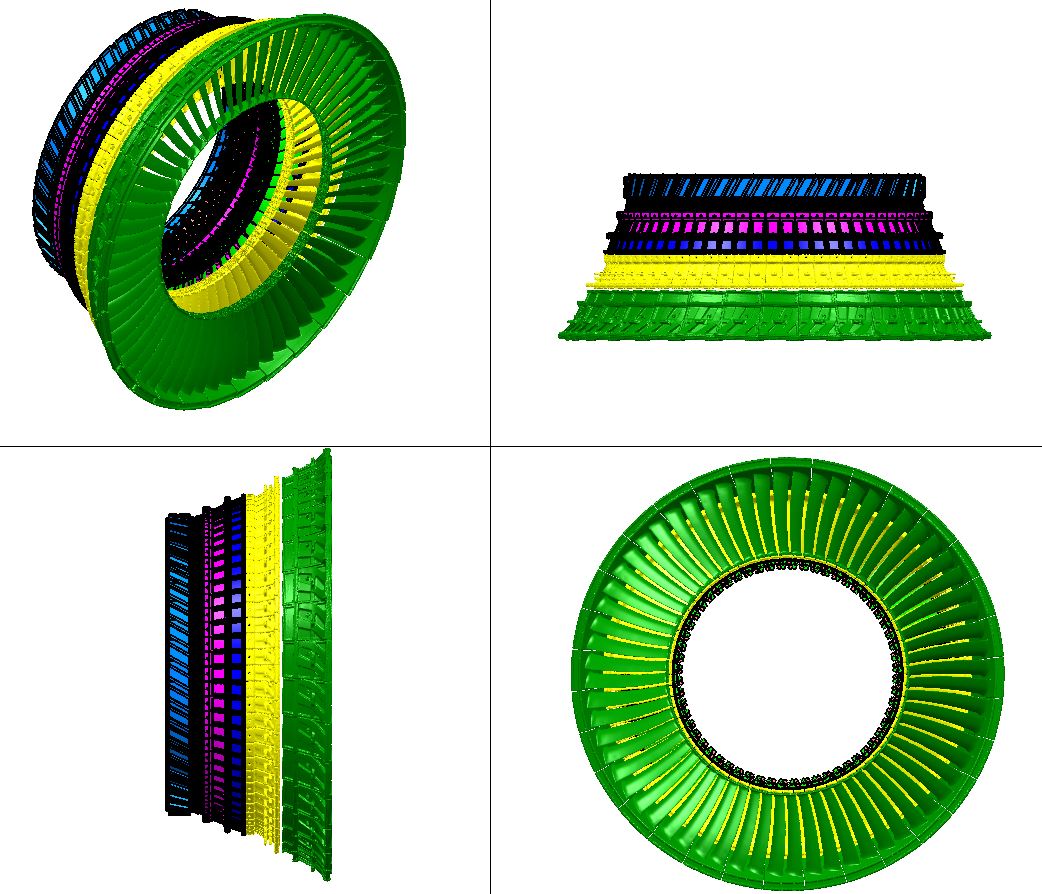

3D model of an example of steam turbine stationary blades

3D model of an example of steam turbine stationary blades

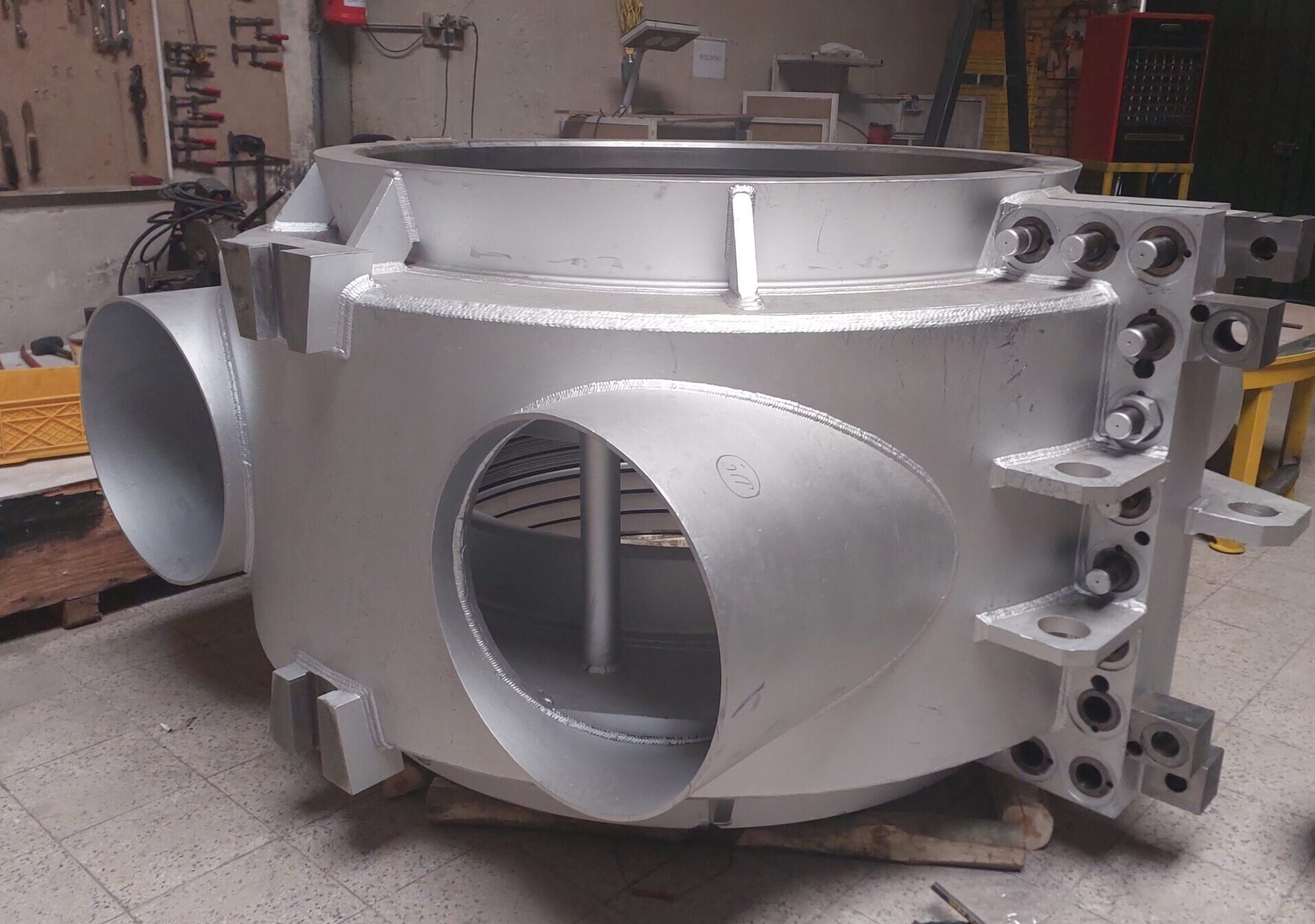

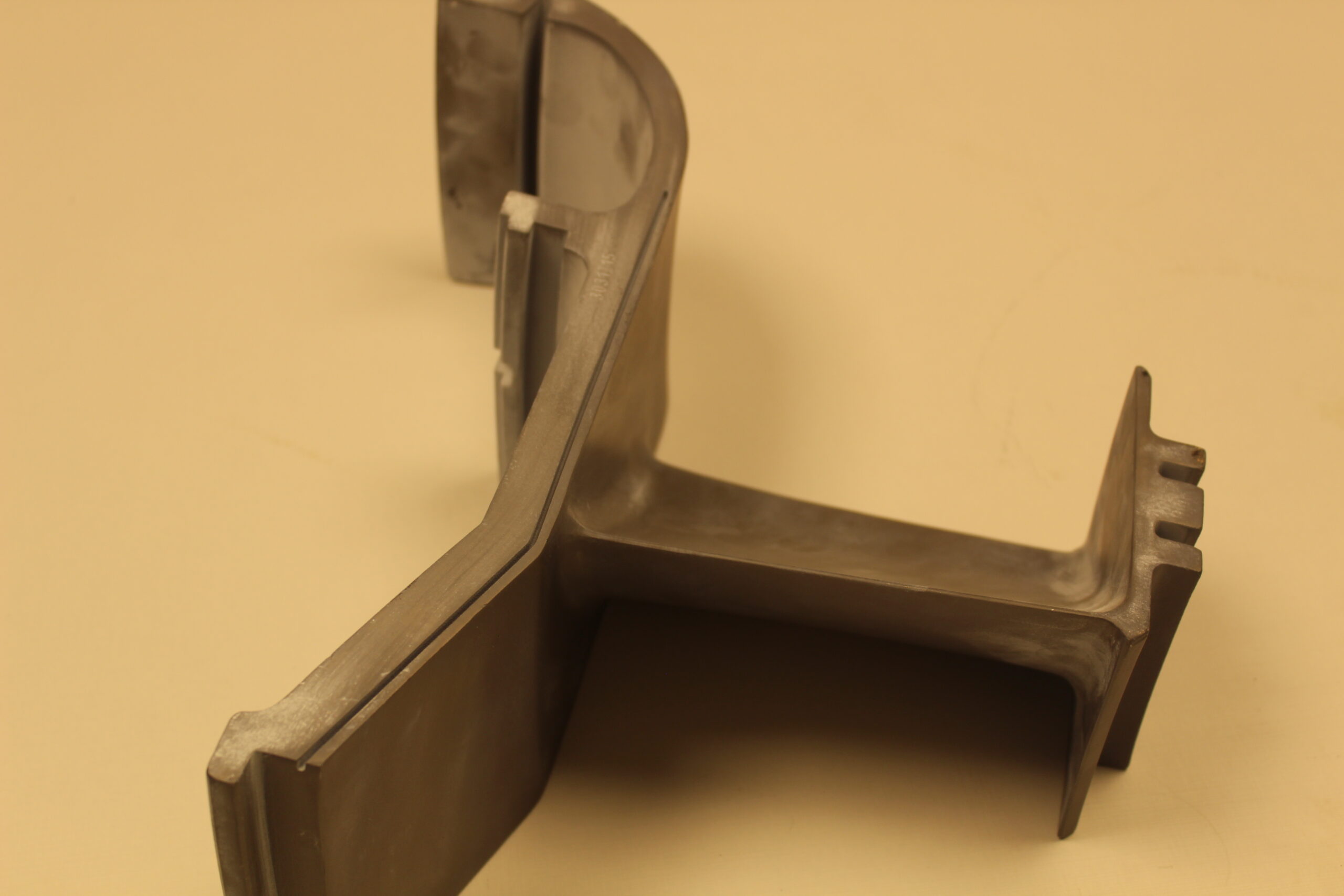

A part of the said project included doing all the above and finally building and controlling the quality of two half-shells of the low pressure part of the steam turbine of Lowshan power plant. Various methods such as casting, welding, grinding, machining, bending and milling have been used for manufacturing.

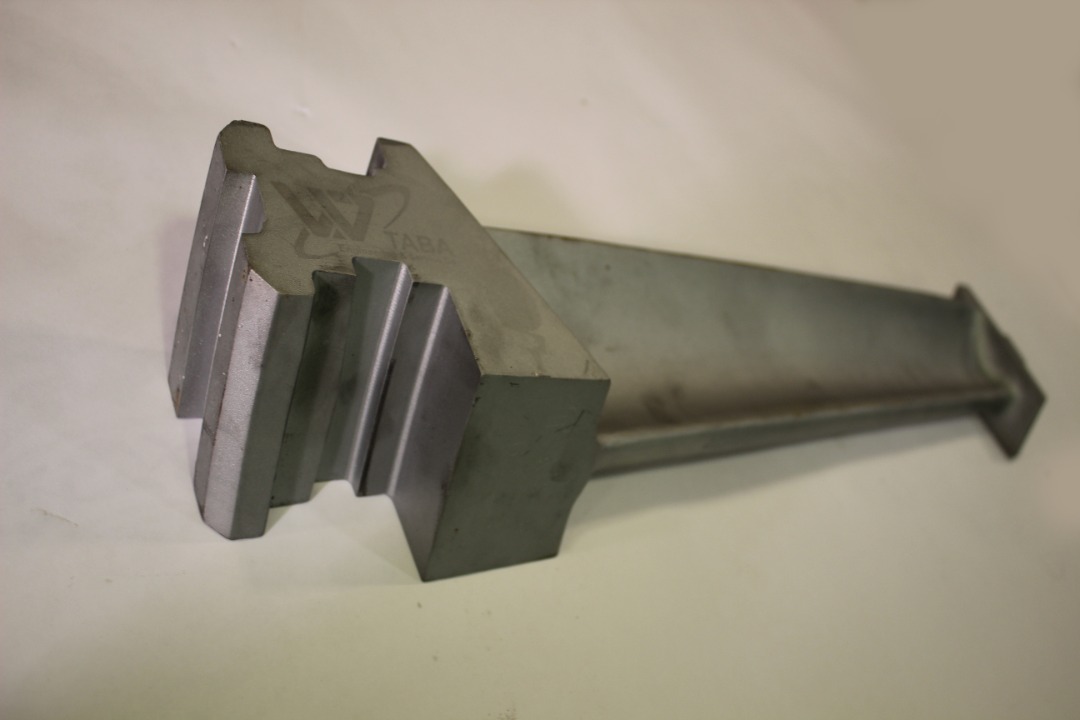

3D model of an example of steam turbine rotary blades

3D model of an example of steam turbine rotary blades

Also, the rows (stages) of one to six stationary blades in the low pressure part of the mentioned steam turbine are symmetrically made with different models and dimensions in each row, using redesign along with reverse engineering with more than 1500 blades and with various challenges. and standard tolerance conditions are assembled on the shell. The stator blades are fixed in a bucket using shrouds. Various and other important parts, including the mentioned shrouds, have been involved in the assembly and finalization of the project, which increases the number of parts of the collection much higher.

3D model of an example of shrouds for one row and one half shell

3D model of an example of shrouds for one row and one half shell

In addition, all the corresponding blades of the rotary rows, which are installed on the turbine rotor, were manufactured and finalized by TABA, which consisted of more than 1600 parts. It should be noted that in the meantime, the engineering team's careful investigation led to measures that created better and more accurate assembly conditions and prevented errors.