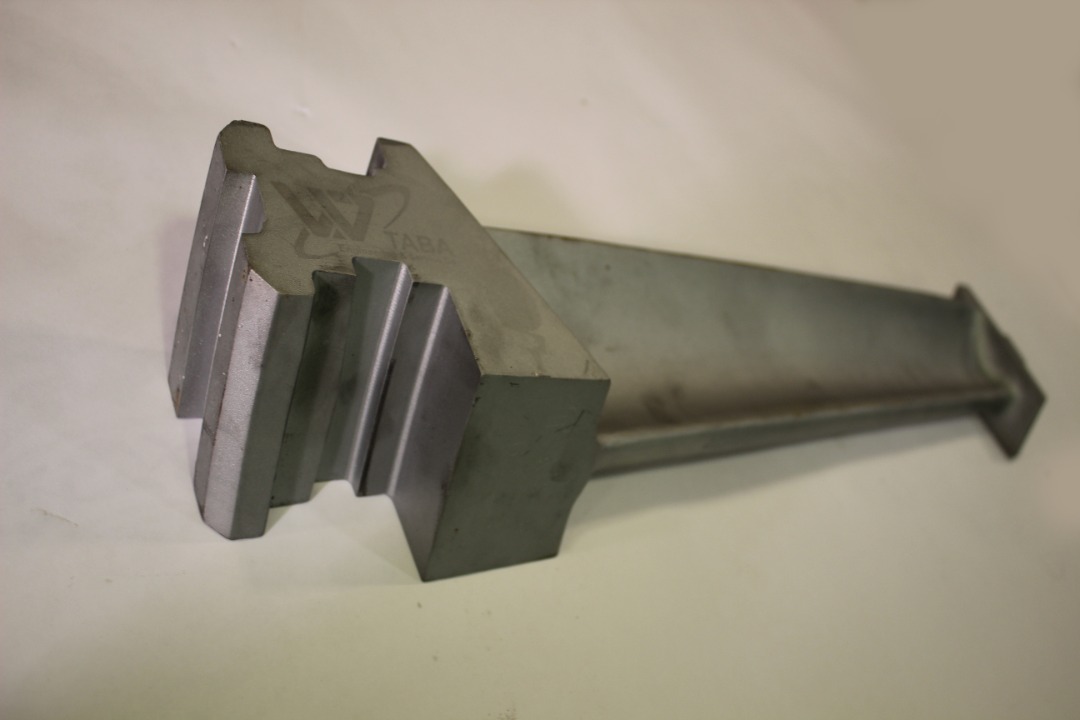

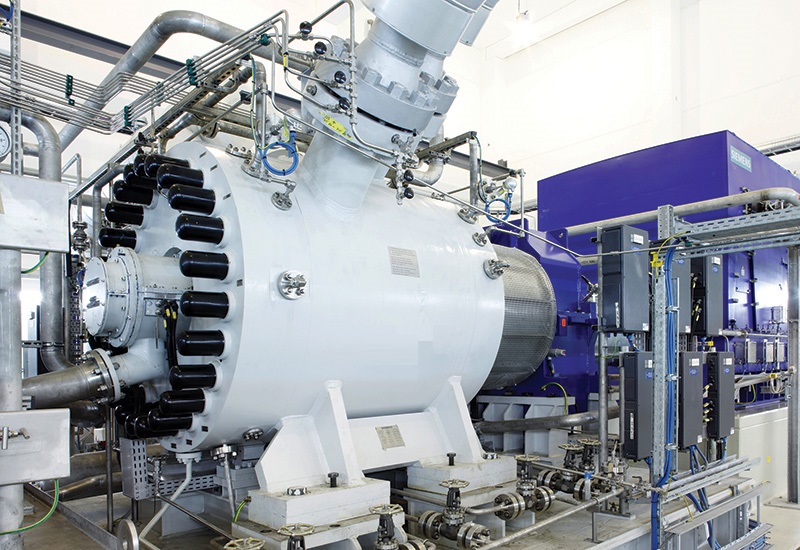

Reverse engineering and manufacturing of generator FD-Fan Blade

| Description | Number | Material | manufacturing process |

| Reverse engineering and manufacturing of FD-Fan Blade of Shahid Salimi Neka power plant steam turbine | 140 | AA 2014 | Forging machining |

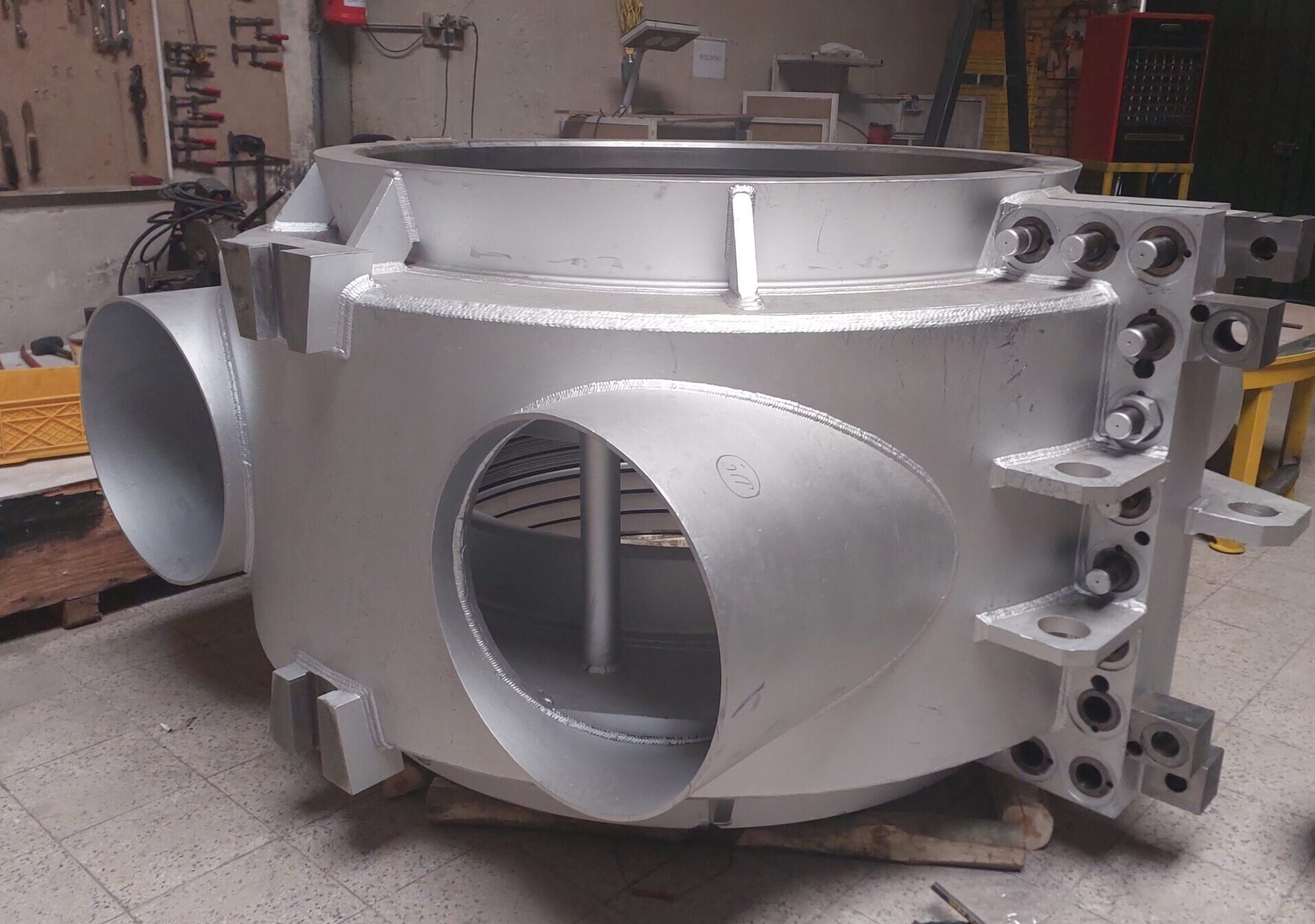

The entire process of manufacturing FD-Fan blades is handled by TABA Co. This process includes:

- Conducting reverse engineering, creating a 3D model, and producing manufacturing drawings with specified tolerances.

- Developing a production plan and all operational procedures, including machining processes and fixture design.